Overcoming the Fragile Nature of Flexible Aerogels for Modern Thermal Insulation Applications

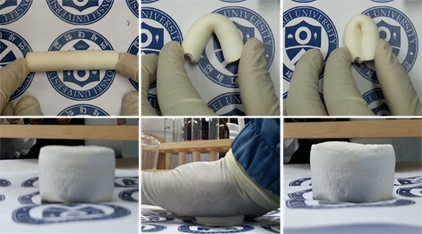

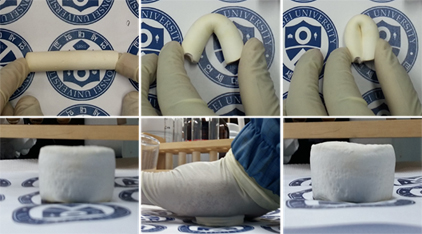

Development of a novel method to create a superhydrophobic silica aerogel composite that is highly flexible and elastic yet still not fragile, which can be used in a wide range of thermal insulation applications.

Aerogels are synthetic ultralight materials derived from gels in which their liquid component has been replaced by a gas. They have been nicknamed “solid air” because of their extremely low density. In particular, silica aerogels have been widely studied and have been applied, for example, as thermal insulators, catalyst supports, and filtration devices. However, their porous skeletal structure makes them very fragile and moisture sensitive, which has limited their potential applications. Previous efforts have been made to enhance the mechanical properties of silica aerogels via coating or cross-linking them with other polymers, but such efforts resulted in denser aerogels that had lost their essential flexibility.

Recently, silica aerogels based on methyltrimethoxysilane (MTMS) have attracted much attention as a candidate for unique thermal insulation applications because of their flexible and superhydrophobic nature. Still, a new way of enhancing the mechanical properties of MTMS-based aerogels was needed. That’s why a research team from Yonsei University, led by Prof. Hyung-Ho Park, proposed a novel way for overcoming the fragile nature of MTMS-based silica aerogels.

Silica aerogels are formed via a well-known sol-gel process. In this process, a precursor solution is prepared in which the building blocks of the aerogel are dispersed. Then, through a process known as gelation, the dispersed particles start to link with each other to form the aerogel. The solvent is then extracted, and the final solid aerogel is obtained.

The research team inferred that a high internal phase emulsion (HIPE) could be used to create a flexible yet resistant scaffold for the MTMS-based aerogel to form on. An HIPE is a highly concentrated emulsion, which is a mixture containing two unmixable phases (such as oil and water), where the dispersed material agglomerates in multiple droplets to form a structure comparable to foam. The dispersion medium (e.g., water) can then be carefully extracted to obtain a stable porous material, referred to as a “monolith.”

By using 2-ethylhexyl acrylate (EHA), the researchers created a monolith named EHA-polyHIPE and used it as a scaffold for the gelation process of their aerogel, as Prof. Hyung-Ho Park explains: “Mesoporous silica networks were grown in the macro-porous EHA-polyHIPE, which supports the fragile flexible silica network at the micron level. This novel way of synthesis allows for overcoming the fragile nature of MTMS-based flexible silica aerogels.”

The team then analyzed the structural, textural, thermal, physical and chemical characteristics of the proposed composite material via numerous and diverse analysis methodologies. They determined that the material possesses excellent water repellent properties, low thermal conductivity, good thermal stability, low density, and high flexibility. “Such unique and extreme properties combined in a single material will open up a variety of applications for corrosion resistant thermal insulation in various fields, such as building insulation, gasoline pipelines in the sea, electrical transformers, etc.”, explains Prof. Hyung-Ho Park.

The team will now test their novel way of overcoming the inherent limitations of standard silica aerogels in real semiconductor processes and devices, further advancing modern applications of complex material technologies.

Recommended Articles

Professor Jong-Hyun Ahn

Novel technique for producing high-resolution micro-LED displays

Professor Seong Chan Jun

Professor Donghyun Kim

Array of hope: Up close and personal with mitochondria in neurons